|

|

"Your source for standard gauge modeling in 1:20.3" |

|

|

|

|

.jpg) .jpg) Track

Making Tools

(updated 9-3-13) Track

Making Tools

(updated 9-3-13)One of the things that makes some varieties of tie strip such a bear to work with is that it is almost impossible to slip two or three rails into the stuff at any rate greater than two or three ties at time. At that rate, one might just as well be hand-laying track. Having suffered this frustration with other brands of tie strip, I have now created a laser-cut plywood jig for holding our F Gauge and Dual Gauge tie strip which makes assembling track a breeze. Even a 10 year-old-girl can do it quickly and accurately! Average time for assembling a 6' long section of dual gauge track is about 5 minutes--but maybe you can do it faster? Pricing and other info can be found here. |

|

Cumberland Model Engineering is very pleased to announce that with the help of my friend Don Niday, we are starting a new spin casting division which will allow us economically to cast our own freight car trucks and miscellaneous detail parts in white metal. After a hair-raising trip to Rhode Island--during which our vehicle broke down at midnight in the middle of a northern New Jersey ghetto, marooning us in the Garden State for nearly a week where we (1) hit a deer, (2) had a grocery store altercation with an aggressive sodomite, (3) found ourselves in the middle of a girls state-wide Soccer Tournament, (4) Dave got a cab ride on NJ Transit, and (5) Don tried his hand at a new circus act as The Human Trebuchet (really, I am not making this up)--we arrived back in Knoxville with 300 pounds of tin alloy, a 160 lbs melt pot, one spin casting machine, and a 600 pound Conley vulcanizer (at right). Don has now put a ventilation stack in his shop, rigged up airlines, and as of Friday, August 23rd, is now casting parts. Our first projects will be getting Don's two standard gauge trucks into production--the 5'-2" wheelbase wooden bolster archbar and the 50 Ton Bettendorf. Next will be the detail parts which go on Dave's 30 ton Southern Railway boxcar. Stay tuned for our next big adventure: Escape From Jersey II in [3-D]! |

.jpg) Test

Builds on 36' Boxcar Kit

(updated 8-27-13) Test

Builds on 36' Boxcar Kit

(updated 8-27-13)So far four test builds of the 30 ton Southern Railway Standard 36' Boxcar are either completed or underway. Mr. Aaron Rohyans of Indianapolis, Indiana has completed the first and is cutting his teeth on #3, a revised design. The car at right is test build #2, being completed by Mr. Mike Minatelli of Newark, Delaware. Mike and his Dad are building an indoor dual gauge layout in F scale. This boxcar is their first piece of standard gauge rolling stock--and it will be servicing, according to Mike, a miniature clothespin manufacturing facility. In reality, I think they must be making toothpicks. Production kits are now much, much closer. See our CME Kits page for updates. Here's a few additional pics: |

%20014(crop300).jpg)  _small.jpg) _small.jpg) _small.jpg) F

Gauge Track Available

(updated 8-27-13) F

Gauge Track Available

(updated 8-27-13)

|

1.5"

Scale / 7.5" Gauge Axle Boxes

(updated 8-26-13) 1.5"

Scale / 7.5" Gauge Axle Boxes

(updated 8-26-13)

|

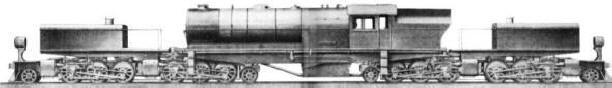

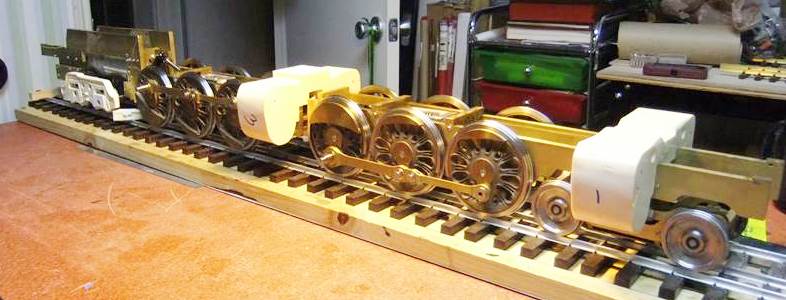

D&RGW

L-105 Chassis Assembled

(updated 8-26-13) D&RGW

L-105 Chassis Assembled

(updated 8-26-13)News comes from my friend Doug Hemmeter that he has received the assembled F scale L-105 chassis from Rodney Edington in Kansas who used the lead truck and driver centers I machined to create the chassis at right. Doug then added urethane cylinder blocks and, at least for now, a temporary urethane trailing truck until a metal one is rapid prototyped. More of Rodney's work creating the brass frame can be seen below: |

%20001.jpg) Side

& Main Rods for the D&RGW L-105

(updated 8-26-13) Side

& Main Rods for the D&RGW L-105

(updated 8-26-13)

Aluminum jigs were then made to hold each side or main rod "blank" for drilling, boring, and in the case of the main rods, fluting. After drawing each main rod as a 3D solid in BobCAD-CAM, each "flute" was created by surface machining a pocket the length of the main rod using a 1/16th inch ball end mill. Since the L-105 was not a roller-bearing side rod equipped locomotive, each ball bearing was hidden with a brass cover pressed into place. Main rod crankpins measured 3/8" OD; front & back & intermediate crankpins were 1/4". A 303 stainless pin connects each knuckle. |

.jpg) CME

Acquires CNC Lathe / Schoolroom Goes Laser

(updated 8-26-13) CME

Acquires CNC Lathe / Schoolroom Goes Laser

(updated 8-26-13)

Where to put a 10,000 pound lathe in a 23.5' x 25' home shop already full of equipment? Well that is a problem. The 1945 Monarch 10EE turret lathe got crowded out of the workshop and has gone into storage. On the other hand, the 120 watt Rabbit Laser USA laser cutter has retreated into the kid's schoolroom. This makes us, I suspect, the only laser-equipped home school in the country. I wonder what Sarah, Emma & Molly will make? What would you make? |

| Continue to CME News 2012 . . . |

|

Last update: 7 January 2014

|

Since

announcing the acquisition of my friend Don Niday's Iron Creek

Shops product line of tie strip and track laying tools last

year, it has been my desire to do another production run of dual

gauge tie strip and expand the line with ready-made-assembled

track. After retrieving the tie strip mold from my friends at

Pellissippi State where it had resided in their Cincinnati

Milcron 400 ton press, I found a local plastics company willing

to let me run the mold on their equipment. My sincere thanks go

to

Since

announcing the acquisition of my friend Don Niday's Iron Creek

Shops product line of tie strip and track laying tools last

year, it has been my desire to do another production run of dual

gauge tie strip and expand the line with ready-made-assembled

track. After retrieving the tie strip mold from my friends at

Pellissippi State where it had resided in their Cincinnati

Milcron 400 ton press, I found a local plastics company willing

to let me run the mold on their equipment. My sincere thanks go

to %20031a.jpg) A

recent commission comes from the live steam sector of the hobby.

Mr. Tim Meyers from south Florida is a live steamer building a

7.5" gauge Chicago & North Western 2-8-2. Tim's C&NW mike will

be unusual in that it is not a USRA prototype, but also because he

intends to build it almost exactly as the prototype, including using

prototypical axle boxes with inserted Babbitt bearings, or "brasses" as they

were called in the industry. How did the big three steam

builders make a prototype locomotive driver axle box--using a shaper of course. How do you make a scale one

in 1:8? Why with a 1980s era Japax wire EDM of course!

A

recent commission comes from the live steam sector of the hobby.

Mr. Tim Meyers from south Florida is a live steamer building a

7.5" gauge Chicago & North Western 2-8-2. Tim's C&NW mike will

be unusual in that it is not a USRA prototype, but also because he

intends to build it almost exactly as the prototype, including using

prototypical axle boxes with inserted Babbitt bearings, or "brasses" as they

were called in the industry. How did the big three steam

builders make a prototype locomotive driver axle box--using a shaper of course. How do you make a scale one

in 1:8? Why with a 1980s era Japax wire EDM of course!

.jpg) After a good

many hours of work, in January of

2013 I completed work on the ball-bearing equipped side and main

rods for Doug Hemmeter's D&RGW L-105 4-6-6-4. These brass rods

are not castings but production rods fabricated through a

combination of wire EDM and cnc milling. The L-105, as readers

of this site may recall, is a one-off model being built by Doug

Hemmeter for a client in southern California; and as such, it

was deemed unnecessary to invest the time and money that would

go into investment cast rods, especially since even investment

cast rods would still have to be drilled and counter-bored for

the insertion of ball bearings. These rods began as pieces of bar

stock whose profile was first cut on two sides using my Japax

wire EDM.

After a good

many hours of work, in January of

2013 I completed work on the ball-bearing equipped side and main

rods for Doug Hemmeter's D&RGW L-105 4-6-6-4. These brass rods

are not castings but production rods fabricated through a

combination of wire EDM and cnc milling. The L-105, as readers

of this site may recall, is a one-off model being built by Doug

Hemmeter for a client in southern California; and as such, it

was deemed unnecessary to invest the time and money that would

go into investment cast rods, especially since even investment

cast rods would still have to be drilled and counter-bored for

the insertion of ball bearings. These rods began as pieces of bar

stock whose profile was first cut on two sides using my Japax

wire EDM. _small.jpg)

%20030_small.jpg)

%20007a.jpg) I

am pleased to announce that as of October 2012, the workshop has

a new resident--a 10,000 pound 1989 model Okuma LB15 CNC lathe.

The Okuma is an industrial workhorse that takes all the juice my

20 horse rotary phase converter can muster (the homemade 20

horse phase converter has itself to be started by a smaller

phase converter of about half that capacity). The Okuma has a

10" Kitagawa hydraulic chuck and a spindle bore just over

2.5"--big enough for the largest F scale wheels and for nearly

any other model train project one might imagine. Tooling is made

by

I

am pleased to announce that as of October 2012, the workshop has

a new resident--a 10,000 pound 1989 model Okuma LB15 CNC lathe.

The Okuma is an industrial workhorse that takes all the juice my

20 horse rotary phase converter can muster (the homemade 20

horse phase converter has itself to be started by a smaller

phase converter of about half that capacity). The Okuma has a

10" Kitagawa hydraulic chuck and a spindle bore just over

2.5"--big enough for the largest F scale wheels and for nearly

any other model train project one might imagine. Tooling is made

by