"Your source for standard gauge modeling in 1:20.3"

|

|

|

"Your source for standard gauge modeling in 1:20.3" |

|

|

.jpg) |

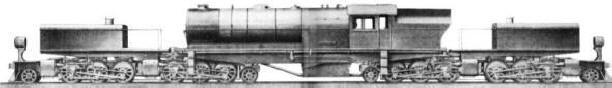

Doug Hemmeter (at left with his wife Mary) is a marine engineer hailing from the Houston area; and over the last several years he has begun to distinguish himself as first a kitbasher of Fn3 locomotives--most notably with a series of D&RGW C-25s based upon the Bachman 2-8-0 drive, built with an all new boiler, cab and tender--and now as a scratch-builder of standard gauge locomotives in F scale. His series of D&RGW M-68 4-8-4s are his first foray into standard gauge. As of November 2011 he has completed two standard gauge 4-8-4s with two more close behind. What comes next: The D&RGW L-105 Challenger, big UP steam, and a C&O 2-10-4. Doug may be contacted at whemmeter@sbcglobal.net and at wdh_marine@sbcglobal.net |

.jpg) |

|

With the construction of a Big Boy, Doug will again have achieved another first in F scale: The first UP steam locomotive model and the first Big Boy (obviously).

Concurrent with the Big Boy will be two

second generation, Otto Jabelman designed Challengers. One of the

two will of course be the 3985 with oil fuel tender. So far this

project is moving along quite well with most of the centipede

tenders having already been cast by Barry Bogs. Bill Brisko's wax

rapid prototype machine has already produced the driver center

patterns, but read on to find out more. . . Doug's usual gang of suspects will be at work on both the F scale Big Boy and the very similar Challenger. So far that accounts for eight people, nine counting Mr. Gary Bartlow who has commissioned not one but three Big Boys! |

|

|

● Dave Queener of Cumberland Model Engineering (your host) is responsible for machining and assembling the 68" & 69" drivers, main & side rods, lead truck, and rapid prototype trailing truck. |

● Michael Aronson is drawing chassis in CAD. |

|

● Bill Brisko of Pacific Locomotive Works is providing the Boxpok driver center castings for the two classes of UP locomotive as well as 36" and 42" steel wheels for the lead, trailing & tender trucks. |

● Rodney Eddington of R and K Railroad Products will be milling the frames and assembling the chassis. |

|

● Ward Hammond will be laser cutting the cabs from styrene. |

● Barry Olsen of Barry's Big Trains has provided the double reduction gearboxes (four per locomotive). |

|

● Barry Bogs has made styrene patterns and cast the centipede tenders for both the Big Boys and the UP Challengers in urethane. Barry is also doing the battery, Airwire and sound installations. |

● Doug Hemmeter of D&M Railroad Backshop is doing all the rest! |

|

Research Materials

(updated 12-9-11) Drawings for this project have come from several sources: First, Roger Goldman offers both Big Boy and Challenger drawings from his extensive collection (as well as 1.5" scale castings for the same). Secondly, Samhongsa in Korea has produced the two locomotives in brass, each in 1:32 scale (once again a good model is worth a words and a few dozen drawings). Finally, additional material has been garnered from the model railroad press. |

|

|

Barry Bogs was tapped in mid-2010 to build the 5 centipede tenders for the UP Big Boy / Challenger project coordinated by Doug Hemmeter and commissioned by Gary Barlow. Barry has sent in a steady stream of photos as he has gone from styrene master patterns to production urethane castings and then completed and painted models. Here are the results thus far:

|

|

| (to be continued . . .) | |

| Next Stop: Coming Soon: The C & O T-1 2-10-4 | |

|

Last update: 9 December 2011

|

|

| Copyright 2004-2009 CumberlandModelEngineering.com. All Rights Reserved |