|

|

"Your source for standard gauge modeling in 1:20.3" |

|

|

|

|

|||

.jpg)  Wire EDM is probably best described as an electronic band saw able to cut any conductive material (brass, steel, aluminum, copper or carbide) using a controlled arc of electricity. The accuracy achievable is phenomenal: Into the ten thousandths of an inch range is common. In my workshop, Wire EDM has been used for:

Since wire EDM is not a fast cutting method, the basic rule of thumb is that where a one-off part is required, the part is small and fiddly, an unusual shape or extreme precision is called for, then wire EDM is the way to go. If you can CAD it, then it can most likely can be cut. Maximum part thickness is 6", length about 24". Here are some sample parts:

|

|||

.jpg) CNC

Milling

(updated 8-28-13) CNC

Milling

(updated 8-28-13)CNC milling is ideal for work where moderate production work and for where complex shapes are required in a part. Our Milltronics Partner I has a work envelope of 31x14 inches. With the addition of a aluminum sacrificial milling table, entire main & side rods can be milled as well as entire locomotive frames in F scale. Some of the projects we have tackled include:

Here are a few pics of some of our past projects: |

|||

.jpg) .jpg) Manual

Turning

(updated 8-28-13) Manual

Turning

(updated 8-28-13)Our Monarch turret lathe is available for small production runs of anything from scale model axles and crankpins to brass bushings and various Delrin parts. One off-work, such as driver tyres and machined driver centers, is done on our Monarch 10EE tool room lathe:

|

|||

.jpg) %20013b.jpg) Laser Cutting & Engraving Laser Cutting & Engraving

(updated 8-28-13)

|

|||

.jpg) .jpg) Custom

CAD

(updated 8-28-13) Custom

CAD

(updated 8-28-13)We also offer custom design work in both 2D AutoCAD and 3D using SolidWorks. Nearly all of our own model work begins at the CAD stage using prototype railroad blueprints which we scan and electronically trace as the basis for all our models. Prototype drawings are available from a number of historical societies, many of whom are now putting there scanned archival images online, or at least a sample thereof. Files can be outputted in their native part or assembly file format or exported in a different format. |

|||

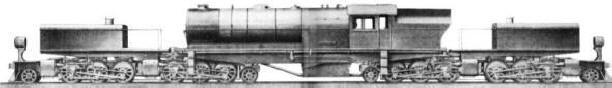

.jpg) %20030.jpg) Steam

Locomotive Driver Machining

(updated 8-28-13) Steam

Locomotive Driver Machining

(updated 8-28-13)We also machine steam locomotive drivers, whether from iron or bronze castings, and apply separate steel tyres, turned from DOM Tube. Drivers up through F scale are rim-insulated for compatibility with 2-rail electric model trains. Drivers for the larger ride on scale are not insulated. Axle boxes can also be created at the time of machining and pressing, or be supplied by the customer. Ride on scale wheel tread follows IBLS Standards unless otherwise specified. A series of tutorial videos on machining driver centers is also in the works, the first of which may be found on YouTube. For more information and a quotation, please Contact Us. |

|||

|

Shop Rates As a small home-based shop with low overhead, we are pleased to be able to offer our services at very competitive rates compared to most industrial job shops:

|

|||

|

Last update: 20 February 2015

| |||

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_small.jpg)

%20004_small.jpg)

%20008_small.jpg)